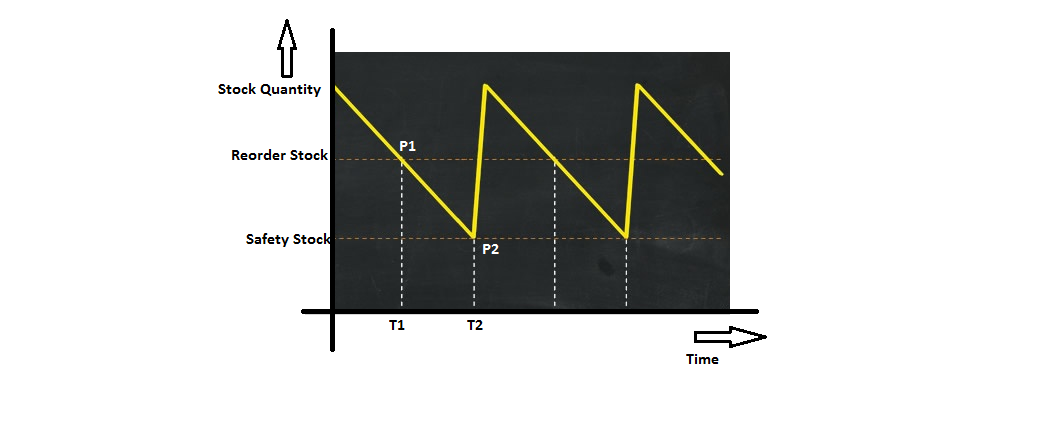

Inventory optimization is taking care that you have just enough stock in hand to satisfy customer demand. In simple terms Inventory Optimization is understanding of when to order the stock and how much to order. This is better explained with the graph below:

The yellow line represents the stock level with respect to time. When orders get shipped the stock decreases with time. The point P1 represents the point at which stock needs to be reordered from the supplier. The time between T1 to T2 is the time where the orders are shipped to customers (from the available Inventory) and time required by supplier to send products to the seller. The point P2 represents the safety point where goods need to be restocked. When it is restocked the above process starts again.

The yellow line represents the stock level with respect to time. When orders get shipped the stock decreases with time. The point P1 represents the point at which stock needs to be reordered from the supplier. The time between T1 to T2 is the time where the orders are shipped to customers (from the available Inventory) and time required by supplier to send products to the seller. The point P2 represents the safety point where goods need to be restocked. When it is restocked the above process starts again.

In practice the sales cycles are not as straight forward and need some advanced algorithm to take care. Inventory Optimization Software automates the complete process and makes it simple to manage.

Stock outs and Over Stock:

Stock outs may lead to loss in sales. Over stock may also lead to losses because excess Inventory takes up floor space and restricts opportunities for new products. This leads to storage costs and also maintenance costs of these stored products. This Inventory usually leads to reduced profits because excess items are sold for lower costs as stock clearance sale. So you should not order more than you need (i.e. customer demand). You should study customer demand and then order the goods. Inventory Optimization Software accurately calculates the demand and also automates the Purchase Order life cycle with the suppliers. Inventory Optimization Software does this in timely manner so that Stock Outs and Over Stocks are avoided.

Inventory Optimization Software for e-Commerce Sellers:

As ecommerce caters to wider geographies, sellers need to stock inventory in different locations. Marketplaces like Amazon/Flipkart push medium to large sellers to keep inventory in multiple fulfillment centres.

Sales for a product are different in different geographies so inventory optimization software would need to take into account sales in that geographies. The big sellers that have many ware houses at different locations have to optimize them at the same time. Also Inventory Optimization Software allows sellers to see the Inventory of all locations at a glance and reorder them at the same time. The available Inventory, Purchase Orders and shipped inventory should be linked. That is if Inventory is ordered from the supplier then Inventory Optimization Software should take into account transient inventory while calculating the recommended additions.

Inventory and Sales based Pricing:

Pricing is crucial for sales of any product but is more crucial in ecommerce. Inventory can be a significant factor in addition to competitive prices in deciding the dynamic price of a product.

In some cases you need to discard certain products because they are out dated or dead stock (no more competitive sales of this product takes place) or high Inventory cost due to high value products or large space is required for storage. In this case a decrease in price would help discard these products faster.

Also you can increase their margin significantly if you can track the surge in sales and dynamically increase the price on products where ever possible without affecting the sales. This can be a significant bonus to you and can ride on the impulsive surge in sales of a product. For example the Fidget spinner was in a great demand for a few months. Customers bought it irrespective of its price hike. You should be able to identify such products in timely manner and dynamically reprice to increase margin.

BoxNsights is advanced Inventory Optimization software in India which also integrates its leading Repricing application to efficiently manage inventory and also adopt smart pricing techniques based on Inventory to increase margins.